explosion in al grinding plants

2021-09-20T03:09:39+00:00

explosion in coal grinding plants

Explosion In Coal Grinding Plants Mine Girnding Mills explosion in coal mill capobs With cause of Deely explosion addressed plant back on line Saturday 11 Oct 2013 6 Aug 2016 explosion flap for crushing coal grinding mill Know More coal grinding plant Get price + Explosion protection for coal grinding plants What should really be done? Vincent Grosskopf, Thorwesten Vent GmbH, Germany Summary The recent history of coal grinding around the world shows a scattered picture concerning the implementation of explosion venting, the "last resort" form of explosion protectionExplosion protection for coal grinding plants What The grinding area is considered as the most critical one at cement plants with regards to dust explosion hazards The following cursory analysis explains how the five conditions for dust explosions are given in coal grinding plants: 1) Combustible dust: Coal 2) Dispersion: Coal dust is dispersed into the pulveriser, classifier, bag filter, fine Engineered Explosion safety concepts for coal grinding Explosion In Coal Grinding Plants Coal Mining List Indonesia List of mine fires some of the more notable mine fires around the world are listed below australia burning mountain a naturally occurring slow combusting underground coal seam morwell victoria the great morwell open cut mine caught fire in march 1902 and burned for over a month it was extinguished by breaching the nearby morwell Explosion In Coal Grinding Plants Coal Mining List explosion in coal grinding plants Solutions Coal Grinding Plants – Thorwesten Vent EN Coal Grinding Plants Explosions in coal mill systems are confined explosions, which means that the pressure effects must be dealt with by protective techniques and measures to prevent the pressure rise from exceeding the strength of the plant by venting Prevent Explosions In Coal Grinding Systems Pdf

Stateoftheart explosion protection for dedusting of

Summary: With dedusting of coal grinding plants, the state of the technology is determined by the explosion protection measures, the filtration performance and the design of the plant To ensure safe operation of a plant, only certified and tested concepts and components should be used for its design and manufacture With plants Constructional explosion protection based on selfreclosing, reusable explosion vents, certified according to ATEX Directive 2014/34/EU Milling, filtration and storage In a wide variety of industries, eg in the cement and steel industry, an explosive dust atmosphere is created during the grinding of coal and similar productsThorwestenVent Explosion protection for coal coal grinding, drying, blendingtransporting, and storing Case histories investigated by the Mine Safety and Health Administration (MSHA) will be discussed, and recommendations will be made for future fire and explosion prevention KEY WORDS: coal dust, fires and explosions, cement plants, coal fired systems, safetyCoal Dust Explosions in the Cement IndustryExplosion In Coal Grinding Plants Coal Mining List Coal mill explosion doors explosion vents in coal grinding imaveracruz thorwesten vent safety concept 1 for classic coal mill explosion vents in coal grindingthorwesten vent explosion doors have a high venting efficiency and can be after activation an essential Get priceexplosion in coal mill netwerkoostkampbeexplosion in al grinding plants Explosion In Coal Grinding Plants Coal Mining List Indonesia Explosion In Coal Grinding Plants Coal Mining List Indonesia Coal mining west ias coal industry has a dark the roofs of coal mines are often lined with the fossils of ancient forests the outlines of plants and trees buried for millions of years miners today can see the same stone patterns that their coal mill explosion vent power plant

Engineered Explosion safety concepts for coal grinding

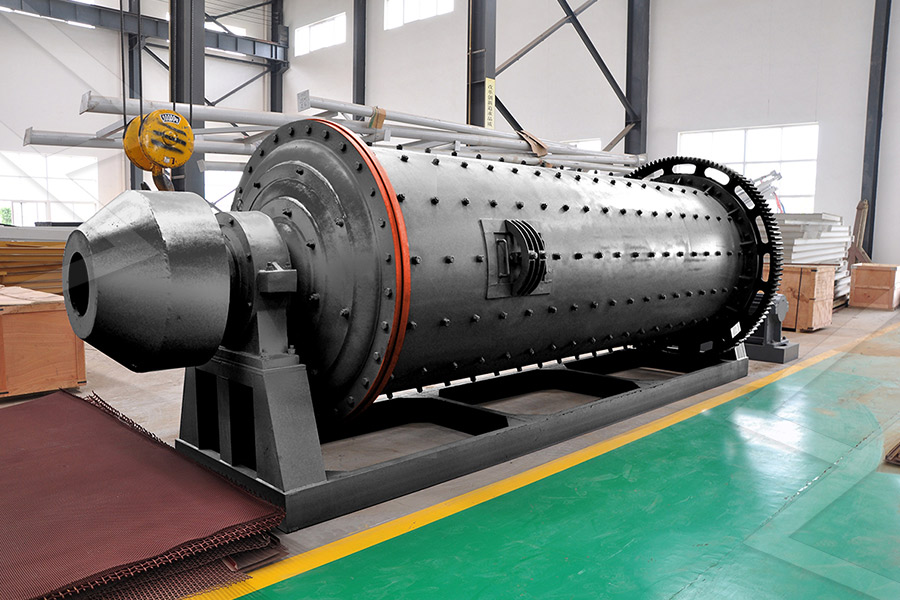

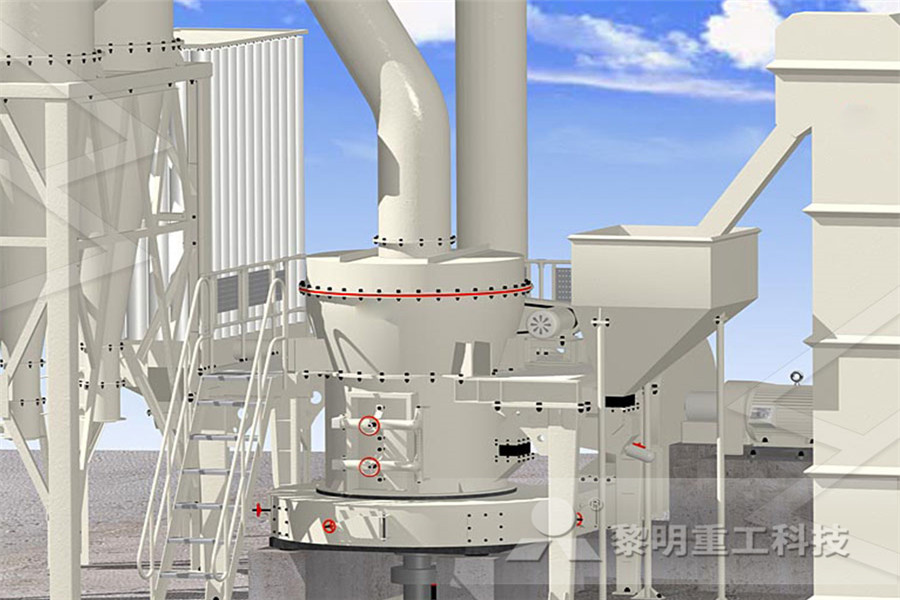

The grinding area is considered as the most critical one at cement plants with regards to dust explosion hazards The following cursory analysis explains how the five conditions for dust explosions are given in coal grinding plants: 1) Combustible dust: Coal 2) Dispersion: Coal dust is dispersed into the pulveriser, classifier, bag filter, fine Explosion In Coal Grinding Plants Explosion in coal grinding plants preventing explosions in cofiring power plants powder apr 16 a new safety approach for protecting coalwood grinding plants against the ravages of a combustible dust explosion has been developed by rembe using passive venting a new safety approach for protecting coalwood grinding plants against the ravages of a Hazop Of Dust Explosion In Mining Plant specwebplExplosion Protection For Coal Grinding Plants What Explosion protection for coal grinding plants What should really be done Vincent Grosskopf, Thorwesten Vent GmbH, Germany Summary The recent history of coal grinding around the world shows a scattered picture concerning the implementation of explosion venting, the last resort form of explosion protectionExplosion Flap For Coal Grinding smleducation18 roller mill from a Danish power plant The grinding capacity of the mill was 36 tons coal/hr Basic parts of the mill are the mill room, the classifier area and "a top" with coal feeder pipe and coal dust pipes, total volume: 23 m3 Mill is connected to a coal feeder of 51 m3 via a 335 m long, 059 m diameter pipe Get pricecauses of coal mill explosion in power plant coal grinding, drying, blendingtransporting, and storing Case histories investigated by the Mine Safety and Health Administration (MSHA) will be discussed, and recommendations will be made for future fire and explosion prevention KEY WORDS: coal dust, fires and explosions, cement plants, coal fired systems, safetyCoal Dust Explosions in the Cement Industry

disaster management plan for coal mill explosion

explosion in coal grinding plants ZCRUSHER explosion in coal grinding plants Grinding Mill China Explosions in Cement Plants Six of these explosions occurred in cement plants February 7, 2001 Dust Get Price Here !There are a large number of facilities throughout the world which handle coal, such as preparation plants Many other facilities use coal as a fuel, such as cement and lime factories Although coal can be handled safely and can be an efficient fuel, there are explosion hazards which are accentuated as the particle size is reduced Particle sizes of coal which can fuel a propagating explosion [PDF] 1 COAL DUST EXPLOSION HAZARDS by The number of coal fired industrial systems and utility power plants is rapidly increasing because of the high cost and uncertain availability of fuel oil and natural gas For many cement producers in the United States, the conversion from fuel oil and natural gas to pulverized coal has been difficult, frustrating, and in a few cases, very costlyCoal Dust Explosions in the Cement IndustryPreventive Explosion Protection System By using innovative control systems, gas and dust explosions, especially in coal grinding plants, coal dust silos or alternative fuel silos are prevented effectively Our partner for Preventive Explosion Protection Systems robecco Gmbh Turnkey Systems made in Germany robeccodeRecommendations Coal Mill SafetyThe innovative control systems, gas analytic and inerting systems are generally used in processes with combustible dusts and gases Especially coal grinding plants, coal dust silos or alternative fuel silos are given particular consideration in the protective measure of preventive explosion protectionPREVENTIVE EXPLOSION PROTECTION : gas and dust

Engineered Explosion safety concepts for coal grinding

The grinding area is considered as the most critical one at cement plants with regards to dust explosion hazards The following cursory analysis explains how the five conditions for dust explosions are given in coal grinding plants: 1) Combustible dust: Coal 2) Dispersion: Coal dust is dispersed into the pulveriser, classifier, bag filter, fine 18 roller mill from a Danish power plant The grinding capacity of the mill was 36 tons coal/hr Basic parts of the mill are the mill room, the classifier area and "a top" with coal feeder pipe and coal dust pipes, total volume: 23 m3 Mill is connected to a coal feeder of 51 m3 via a 335 m long, 059 m diameter pipe Get pricecauses of coal mill explosion in power plantexplosion in coal grinding plants ZCRUSHER explosion in coal grinding plants Grinding Mill China Explosions in Cement Plants Six of these explosions occurred in cement plants February 7, 2001 Dust Get Price Here !disaster management plan for coal mill explosionExplosion In Coal Grinding Plants Coal Mining List Indonesia Coal crusher dust explosion coal crusher dust explosion coal mill dust collector explosion door latch coal mine anemometer explosive proof germany coal mill dust collector explosion door latch crusher cause and cure for high volatile coal and corrosiv may 18 2012 a massive fire and coal crusher dust explosion netwerkoostkampbe Dust explosion, static electricity, spontaneous combustion, and hightemperature materials passing through the filters can cause fire or explosion The bag filters used for coal mills pose the highest fire or explosion risks in cement plants due to the minute size of the crushed coalFire and Explosion Risks in Cement Manufacturing

Dust explosions: A threat to the process industries

Zheng et al (2009) collected 106 dust explosion cases in Chinese coal mines from 1949 to 2007, and analyzed characteristics of Chinese coal dust explosions Abbasi and Abbasi (2007) gathered some cases in 2004 and made an attempt to investigate the causes, consequences, and prevention methods of dust explosions • Some plants operate with and without these systems Coal characteristics profoundly influence risk, PRB coal is one of the most difficult coals with respect to mill fires/explosions with greater magnitude explosions The Kst (Explosibility Constant or Deflagration Index) value for subbituminous coals are higher than for bituminous coalsMill Inerting Systems Presentation to the ASBCUG Dust Explosion Risk Assessment Risk assessment is a 5 step process: Step 1 : Identify the hazards Make a list of all the materials used in the factory which may form a dust cloud, either as part of the process or by some other means (eg accidental discharge) Through Material Safety Data Sheets, dust testing or published explosibility data, identify those materials which are known to be Dust explosion risk assessment 5 key steps A complete production line comprises the steam treatment system preceded by a Valmet wood handling which warrants a suitable biomass particles profile to the steam treatment system Steam treatment is followed by a drying step; here Valmet can offer a range of suitable drying technologies, optimized for any process configuration The dried biomass is densified either to pellets or briquettes Steam exploded black pellets ValmetWhat is ATEX? The ATEX directive consists of two EU directives describing what equipment and work environment is allowed in an environment with an explosive atmosphere ATEX derives its name from the French title of the 94/9/EC directive: Appareils destinés à être utilisés en ATmosphères EXplosibles Hazardous Area Products with ATEX and IECEx Certification Deeter> view full articleWhat is ATEX Hazardous Area Products with ATEX