rod mill power vs ball mill

2020-11-23T06:11:13+00:00

What are the differences between ball mill and rod

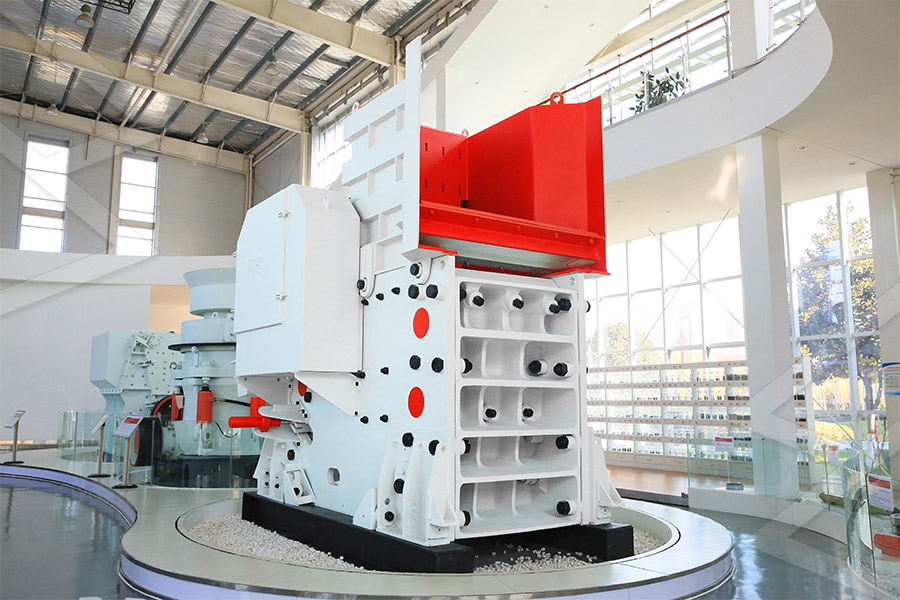

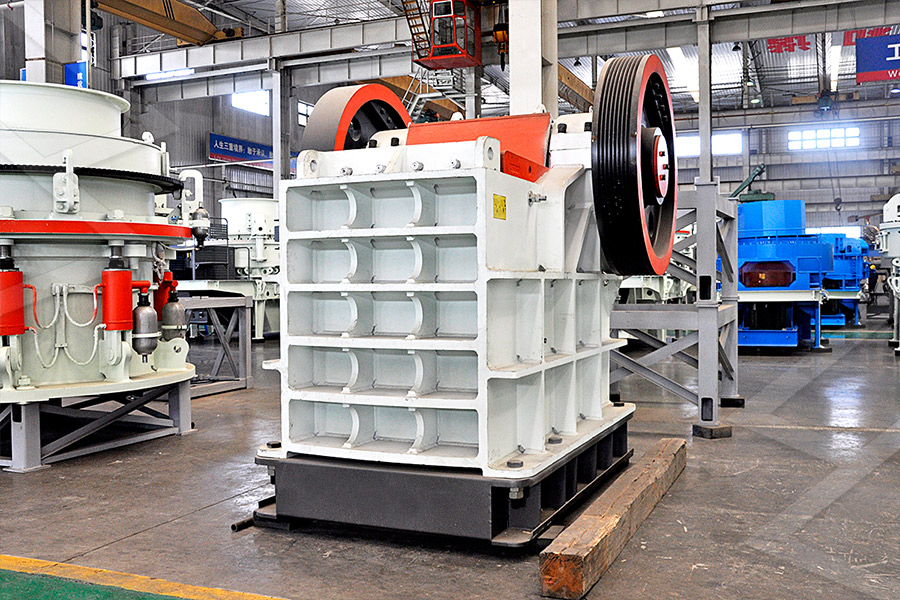

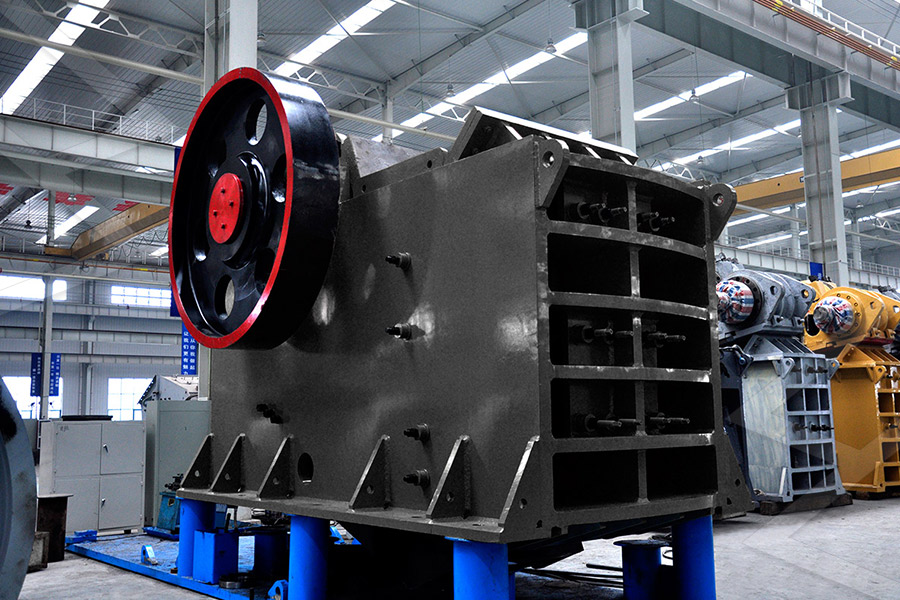

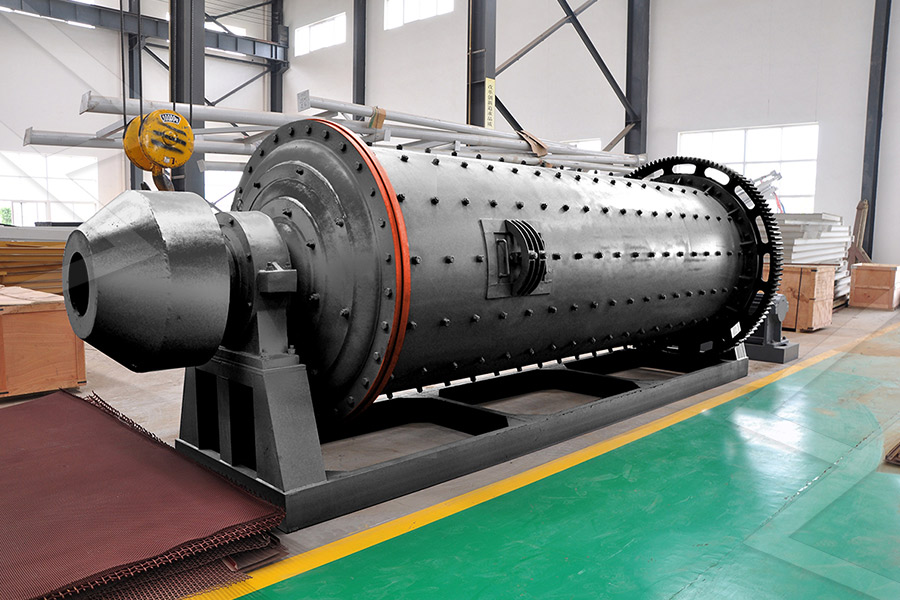

Recommendation of ball mill and rod mill Ball mill and rod mill are suitable for different materials 1 Selection by material's hardness Ball mill has a strong adaptation of material, and it is suitable for grinding hard materials, such as slag, iron ore, copper ore, etc Rod mill is suitable for grinding brittle material, such as rare metals Because of this, the rod mill can effectively reduce 1″ feed size to 10 mesh or finer in open circuit The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load Rods in place weigh approximately 400 pounds per cu ft and balls Ball Mills vs Rod Mills 911 MetallurgistRod Mill Power Vs Ball MillDelap Ball Mill Vs Rod Mill Difference between ball mill rod mill difference between sag mill vs ball mill mech4study oct 12 2017 today we will learn about difference between sag mill vs ball mill a mill is a machine by which solid or hard materials are broken into smaller pieces by rod mill power vs ball mill sscafepl Ball mills Ball mill (Fig 1) is same kind of mill as rod mill, except that it is filled with balls instead of rods Because of balls have greater ratio of surface area than rods they are more suitable for fine grinding Balls are also lighter, so the kinetic energy of a single dropping ball is smaller than a rodGrinding Mills and Their Types – IspatGuru The rod mill motor power is in horsepower at the mill pinionshaft For different length rod mills power varies directly as rod length For difference between new and worn liners increase power draw by 6%, and adjust for bulk density per Table A Wet grinding rod mills Rod Mill Design Power Draw Mineral Processing

Overflow VS Grate Discharge Ball or Mill Why Retrofit

Grate Discharge Ball Mills have shown 25% to 45% more tonnage ground and a substantial reduction in power consumed per ton of material compared size for size with overflow mills To illustrate the characteristics of various type mills we have shown the types of discharge for rod mills and ball mills There are essentially four types of rod mill Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting This commutation is an essential part of many processes Various kinds of mills Difference Between Sag Mill vs Ball Mill mech4study When calculating rod mill power for a rod millball mill circuit, do not allow for improvement in the ball mill performance due to receiving rod mill feed If the rod mill feed is produced with open circuit crushing, apply a 12 inefficiency factor to the power calculated for the rod milling stage onlyRod Mill Design Calculations Mineral Processing The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific Ball Mill Design/Power Calculation LinkedInThough ball mills are used more often rod mills can be the better option for specific mining ores and larger site projects In a ball mill the actual balls in the machine need to cascade in order for the grinding to be accomplished Because of this more energy is needed to power up a ball press as opposed to a rod Comparing Used Ball Mills Vs Used Rod Mills

Ball Mill Vs Presentation spielgruppeheuguemperch

May 08, 2020 Rod Mill VS Ball MillShape And Internal Structure The Shape Design Of The Rod Mill And The Ball Mill Are Similar, And Both Adopt Horizontal Rotatable Cylinders The Internal Structure Of The Two Is Basically The Same There Are Grinding Media In The Barrel, As Well As Feeder, Gears, Feed End, Discharge End, Transmission Device, Etc Rod Mill It accounts for up to 40% of the total power consumption in mineral processing plant operations So, selecting the efficient solution for grinding section is very important Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industriesBall MillRod Mill Grinding System Used in Mineral vs electric grinder rod ball mill theviewparktowncoza vs electric grinder rod ball mill rod mill vs ball mill AM King Ball Mills vs Rod Mills Ball mills and rod mills are both excellent mining machines for grinding ores into fine powders and particlesThough ball mills are used more often rod mills can be the better option for specific mining ores and larger site projectsVs Electric Grinder Rod Ball Mill hirtimrhyhofch Ball mill vs Rod mill Similarities The working principle is basically the same Regardless of the ball mill or the rod mill, when the cylinder rotates, the grinding media (ball or rod) installed in the cylinder body are lifted to a certain height, and then they are thrown at a certain linear velocity, so the grinding media causes some impact Ball Mill Machine For Sale FTM Machinery1 Ball Mill: The grinding medium is mainly short steel bar or steel ballThe grinding force of ball mill is large, the structure is light, and the rotation speed is stable 2 Rod Mill: The grinding medium is mainly steel rod, the diameter of steel rod is mostly between 50100mm, and the grinding time is longer 3 Gravel Mill: The grinding medium mainly includes pebble, gravel, sand What is Ball Mill How Many Types of Ball Mills MC

Difference Between Sag Mill vs Ball Mill mech4study

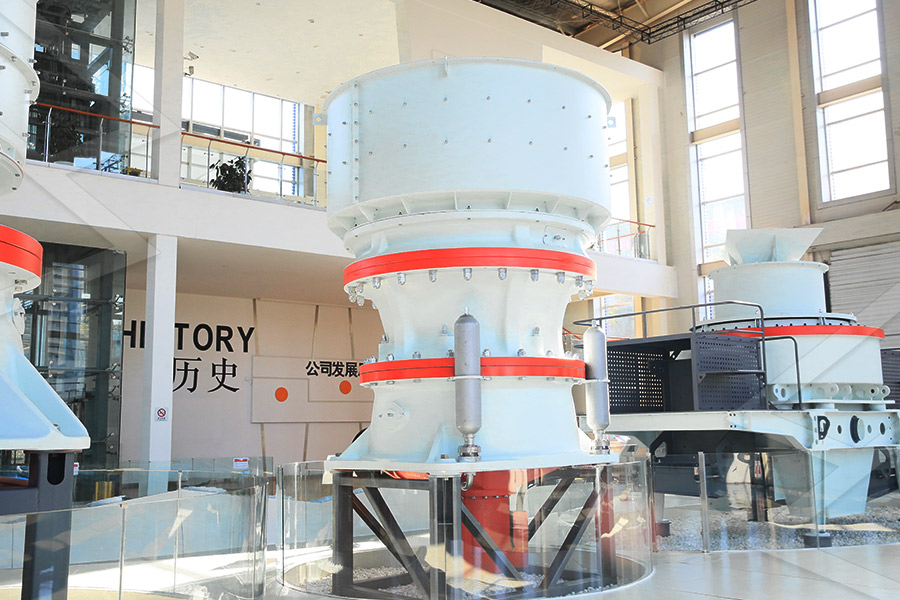

Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting This commutation is an essential part of many processes Various kinds of mills are there with which different material processing takes place Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grinding (SAG) mills, balls of various sizes in Ball Mills and less commonly these days, steel rods in Rod MillsWhat’s the difference of Ball mill, SAG mill, AG mill?Ball mill for sale In all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, froth flotation, the working principle is to prepare fine size ores by crushing and grinding often with rock crushers, rod mill, and ball mils for the subsequent treatmentBall Mills Industry Grinder for Mineral Processing conventional crushing and grinding circuits (crusherrodball mill or crusherball mill) By the 1970s, the application of conventional tended to be limited to relatively low capacities circuits The majority of modern grinding circuits include a SAG mill, a ball mill and/or a Orway Mineral Consultants Canada Ltd Mississauga, ON May 08, 2020 Rod Mill VS Ball MillShape And Internal Structure The Shape Design Of The Rod Mill And The Ball Mill Are Similar, And Both Adopt Horizontal Rotatable Cylinders The Internal Structure Of The Two Is Basically The Same There Are Grinding Media In The Barrel, As Well As Feeder, Gears, Feed End, Discharge End, Transmission Device, Etc Rod Mill Ball Mill Vs Presentation spielgruppeheuguemperch

Ball MillRod Mill Grinding System Used in Mineral Milling

It accounts for up to 40% of the total power consumption in mineral processing plant operations So, selecting the efficient solution for grinding section is very important Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting This commutation is an essential part of many processes Various kinds of mills are there with which different material processing takes placeDifference Between Sag Mill vs Ball Mill mech4study Ball mill vs Rod mill Similarities The working principle is basically the same Regardless of the ball mill or the rod mill, when the cylinder rotates, the grinding media (ball or rod) installed in the cylinder body are lifted to a certain height, and then they are thrown at a certain linear velocity, so the grinding media causes some impact Ball Mill Machine For Sale FTM Machinery1 Ball Mill: The grinding medium is mainly short steel bar or steel ballThe grinding force of ball mill is large, the structure is light, and the rotation speed is stable 2 Rod Mill: The grinding medium is mainly steel rod, the diameter of steel rod is mostly between 50100mm, and the grinding time is longer 3 Gravel Mill: The grinding medium mainly includes pebble, gravel, sand What is Ball Mill How Many Types of Ball Mills MC Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grinding (SAG) mills, balls of various sizes in Ball Mills and less commonly these days, steel rods in Rod MillsWhat’s the difference of Ball mill, SAG mill, AG mill?

Powder metallurgy – basics applications

The ball to charge ratio may be 5:1, 10:1, 15:1 This method is more efficient in achieving fine particle size Rod mills: Horizontal rods are used instead of balls to grind Granularity of the discharge material is 4010 mm The mill speed varies from 12 to 30 rpm Planetary mill: High energy mill widely used for producing metal, alloy, and 4 A mill spindle is designed for both down load (axial, like a drill press), and also side load (radial) That is why a mill spindle runs in tapered roller bearings (or deepgroove ball bearings) inside the quill 5 The spindle isn’t just for drill chucks — use any R8 compatible device — end mill holders, collets, slitting saws, etc 6CHOOSING USING A MILLING MACHINE Ball Mill Wio, BWio 86 Circuit Wio, OWio 146 Bond Ball Mill Work Index, BWi, kWh/t 134 Bond Rod Mill Work Index, RWi, kWh/t 181 Table 1 Example of AG/SAG Ball Mill Circuit Wio Calculations [1] [2] ABstrAct Optimum use of power in grinding, both in terms of grinding efficiency and use of installed capital, can have a large effect on Application of Operating Work Indices in Autogenous Rely on our proven track record of SAG and AG Mill superiority Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore onlyAutogenous and SemiAutogenous Mills