jaw large jaw crusher vibrating big reason

2023-01-04T20:01:45+00:00

Jaw Crusher Vibrating Big Reason atlantikwallarchiefnl

Jaw Crusher Vibrating Big Reason Dec 22 2020 small jaw crushers are hot in market the jaw crusher is a primary rock crushing equipmentin recent years the market for small or mini jaw crushers has been hot and the orders received by our company have continued to increase which is larger than beforeLarge jaw crusher vibrating big reason Comprehensive Industry Document Stone Crushers Central Bridges Canals etc Stone Crushers also need electricity supply and large number It is for these reason that most Stone Crushers are These type of crushers are mostly located near to the bigger cities and in the vicinity of major Big vibrating for stone crusher beckersmuehledelarge jaw crusher vibrating big reason keithkirsten Aug 29, 2016 3 Sep 2013 The failure of hammer crusher is vibration Causes Of Hammer Crusher High on the foundation of jaw stone crusher impact of vibration on the foundation of jaw stone crusher Get Price; The reason solution of the fault of the crusher jaw crusher vibrating reason szczyrkonlineplChina Big Capacity Jaw Crusher, Big Capacity Jaw Crusher China Big Capacity Jaw Crusher manufacturers Select 2021 high quality Big Capacity Jaw Crusher products in best price from certified Chinese Capacity 1 Ton manufacturers, Big Electric Motor suppliers, wholesalers and factory on MadeinChina Chatbig capacity jaw crusher from shanghai china manufacturerSolutions 100T/H Limestone Crushing Line In Switzerland Main Equipments: PE series jaw crusher, impact crusher, sand maker, raymond grinding mill, vibrating screen and vibrating feeder 200350T/H Sand Production Line In Turkey The 200350t/h sand production line in Turkey is designed in August, 2014, and put into use in October Jaw Jaw Crusher And How It Works, Jaw Crusher

the big jaw crusher

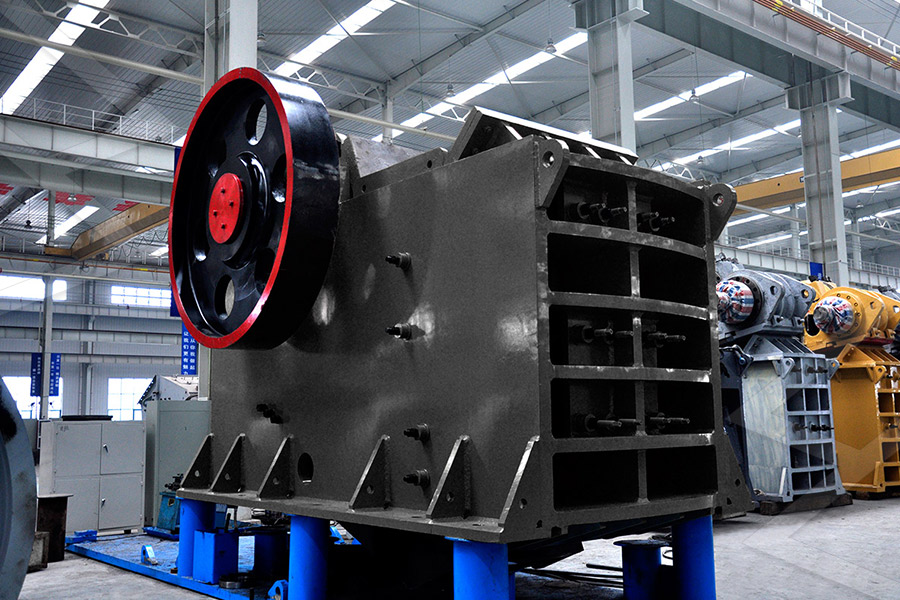

Measurement Big Jaw Crusher measurement big jaw crushers Crushing Plant CEC large jaw sizes are 24 x 36, 30 x 42, Jaw crusher has the large crushing ratio, average particle size Take Our Service »Crushing PlantJaw Crusher144 Мбcrusher The Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for the primary crushingbolts Fixed jaw plate jump Jaw plate asteners loose Fasten the bolts The temperature of bearing too high 1lack of lubricant oil 2oil dirty 3bearingBearing In Jaw Crusherhow a jaw crushing machine works pdf How A Jaw Crushing Machine Works ilcapriccio how a jaw crushing machine works pdf The jaw crusher is not so efficient a machine as the gyratory crusher described in the next paragraph, the chief reason for this being that its crushing action is confined to the forward stroke of the jaw only, whereas the gyratory crusher does useful work during the get how a jaw crushing machine works MC World In fact, this flywheel plays in the operation of the jaw crusher Crucial role The main reason is also from the working principle of the jaw crusher The jaw crusher is an indirect working device, which causes the resistance on the eccentric shaft to change, the The role of the flywheel in the jaw crusher Industrial Measurement Big Jaw Crusher measurement big jaw crushers Crushing Plant CEC large jaw sizes are 24 x 36, 30 x 42, Jaw crusher has the large crushing ratio, average particle size Take Our Service »the big jaw crusher

Best Quality Jaw Crusher With Large Crushing Ratio

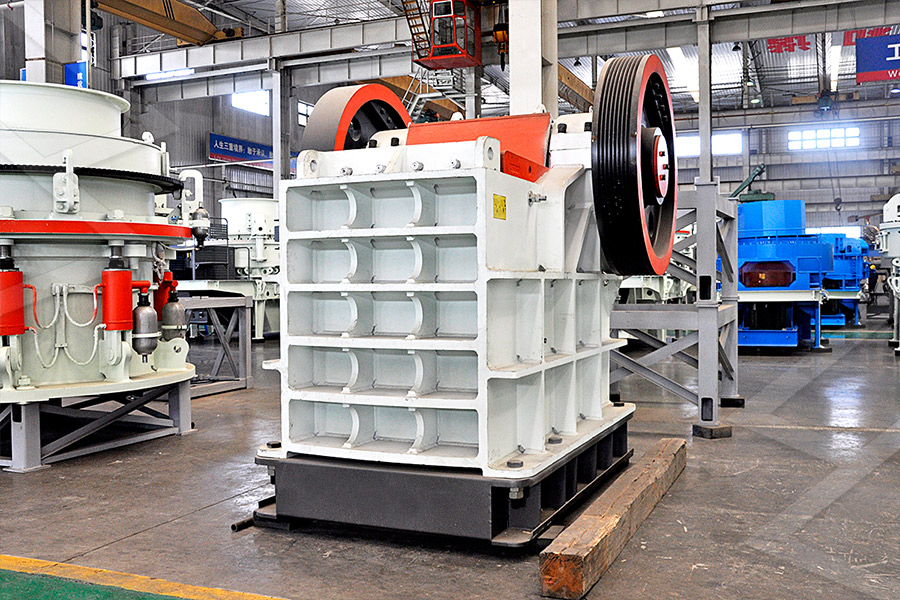

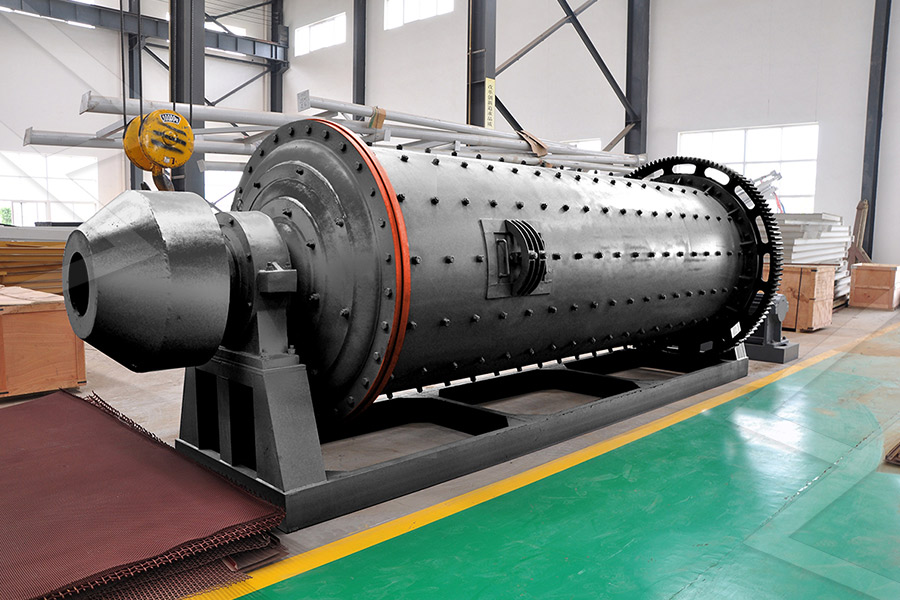

Jaw crusher is used as the primary crusher for the ores and rocks with different hardness so that people sometimes call it primary jaw crusher Since the advantage of large crushing ratio, big crushing force, easy to maintain, low failure rate, it is a suitable choice for the mining industryThe BOYD Crusher is the world’s first double acting, fine jaw crusher Its patented design includes top and bottom driven moving jaws, enabling the maximum amount of crushing in a single pass The Big BOYD Crusher takes lump sizes of up to 150mm pieces and crushes them to 10mm or less in a single pass, reducing time for every samplejaw crusher nicaragua AtaFinch The 48 by 42inch jaw crusher and smaller sizes are forcefed by an automatic highpressure lubricator to the swing jaw, pitman, and main bearings as illustrated in Figure 1 A motordriven pump forces the lubricant through pressure buildup cylinders and out to distributors which dispense a precise amount to each of the points on the bearingsJaw Crushers for Sale 911 MetallurgistReasons To Use Jaw Crushers Dec 29 2014 the main feature which makes the jaw crusher to be different from all other crushing machines that can be found on the market are the fixed and moving jaw plates a large number of companies from all around the world use jaw crushers for various crushing applications the main reason for this is that the jaw crushers offer more benefits andUse Of Jaw Crusher tuinaanlegdenhaagnlSmall Jaw Crusher Price Analysis the Reason for the Hot Dec 22, 2020 A small mobile jaw crusher Get Latest Price small mobile jaw crusher can move freely to the site It reduces site waste with its combination of a jaw crusher Rocks can be crushed to the output size of 1/2 to dust, which can be used as a subbase materialbiggest mobile jaw crusher SmartTech

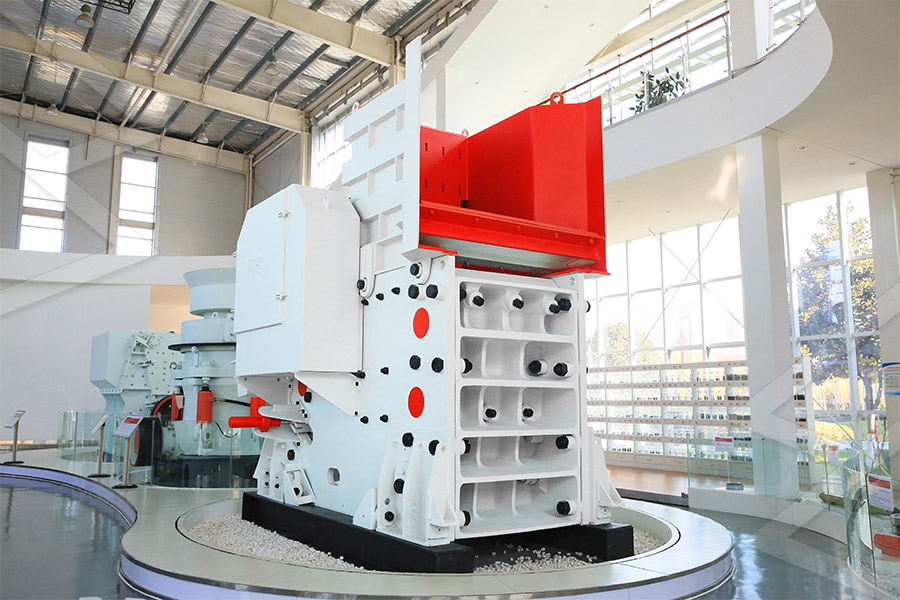

Popular Large Jaw Crusher PE1200*1500 Company

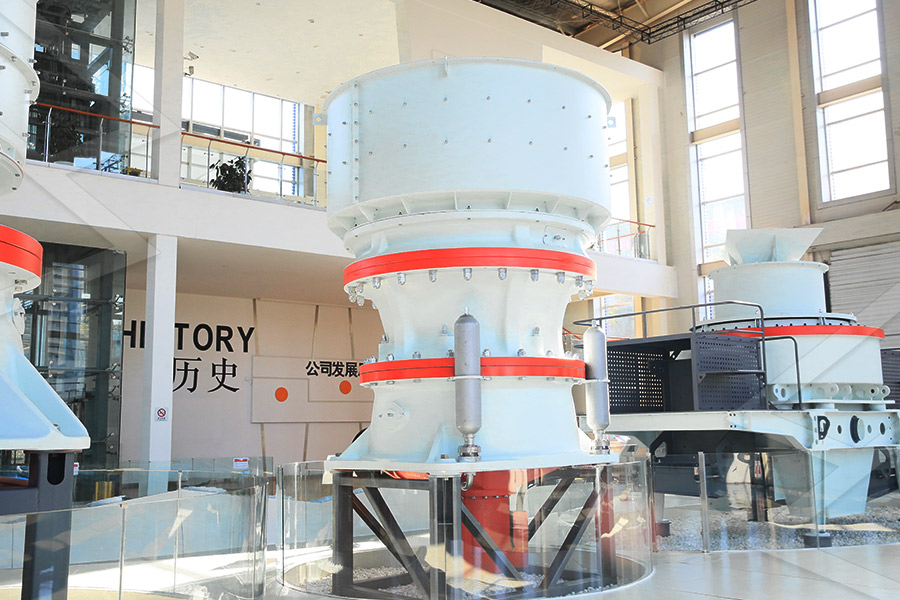

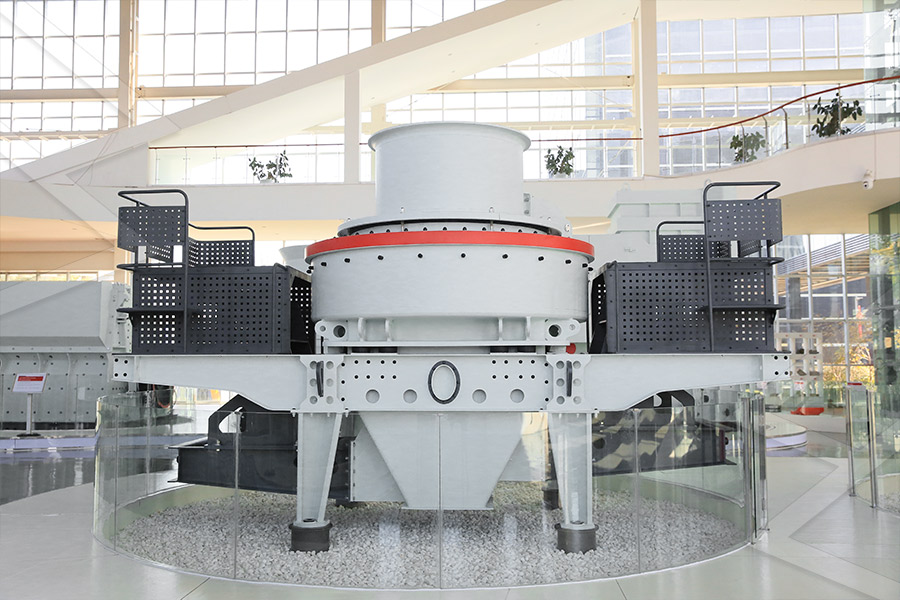

As a leading manufacturer of the crushing and screening equipment, Kefid Machinery Co,Ltd is the absolute leader in the domestic and international market in designing and produce the large jaw crusherThe PE1200*1500 jaw crusher with capacity of 650800t/h, maximum feeding size of 1020mm, discharging opening range of 150300mm is very popular in the mining equipment market; it This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate and movable jaw gets bigger when the jaw rising Jaw Crusher Handbook Stone Crusher PDF JXSC Mine Choose jaw crusher or gyratory crusher The general largescale crushing plant will choose the gyratory crusher as the primary crusher, except the viscous materials crusher plant Because the capacity of the gyratory crusher is large, Big crushing ratio The small mine crushing and quarries use jaw crusherDifference Between Jaw Crusher and Gyratory Crusher Primary coal crusher: These crushers are used for bigger coal sizes and have different types such as the coal jaw crusher, the coal hammer crusher, and the ring granulator (b) Secondary coal crusher: These are used when the supplied coal is big enough to be handled by a single crusher The primary crusher converts the feed size to be Crushers an overview ScienceDirect TopicsManufacturer of : "Jaw Crusher India " Jaw Crusher, Stone Crusher, Vibrating/ Rotary Screens, Conveyors, Truck Loaders Quarry Equipments Jaw Crushers – Osborn South Africa: Excellent nip angle Fabricated main frame and swing jaw Reversible jaw dies for maximum wear Relief / adjustment Osborn Hadfields Jaw Crusher (Double Toggle)Double Toggle Jaw Crushers Crusher Mills, Cone

Jaw Crusher Handbook Stone Crusher PDF JXSC Mine

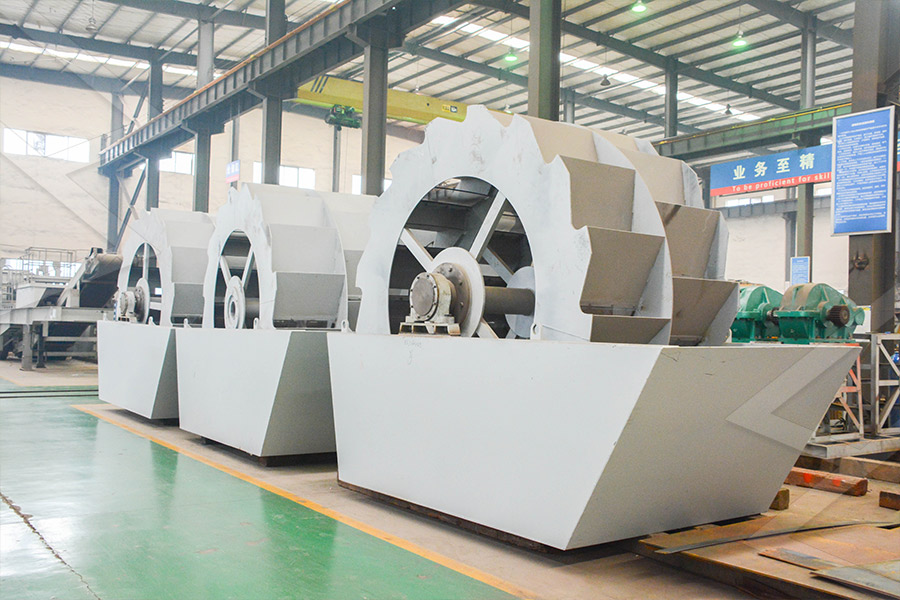

This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate and movable jaw gets bigger when the jaw rising Reasons To Use Jaw Crushers Dec 29 2014 the main feature which makes the jaw crusher to be different from all other crushing machines that can be found on the market are the fixed and moving jaw plates a large number of companies from all around the world use jaw crushers for various crushing applications the main reason for this is that the jaw crushers offer more benefits andUse Of Jaw Crusher tuinaanlegdenhaagnlvibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h to 600t/h To meet customer's specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plantgreasing technique for jaw crusherJaw Crushers For Sale In Nigeria Hitlers Hollywood More details jaw crushers for sale in nigeria in nigeria jaw crusher is the earliest crushing equipment which has simple structure strong reliable work easy maintenance and repair and less production and construction costs jaw crusher is generally divided into two kinds compound pendulum and simple pendulum which are mainly used for rough and easy maintenance jaw crusher in nigeria questions In fact, this flywheel plays in the operation of the jaw crusher Crucial role The main reason is also from the working principle of the jaw crusher The jaw crusher is an indirect working device, which causes the resistance on the eccentric shaft to change, the The role of the flywheel in the jaw crusher

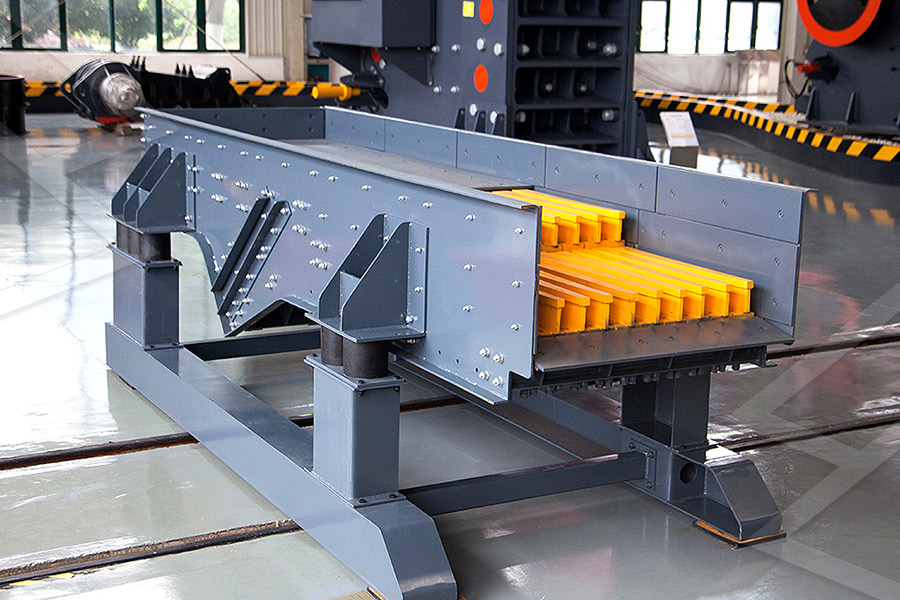

PQ University Lesson 7 Crushing Secondary

Jaw crusher units with extralong, articulated crusher jaws prevent coarse material from blocking while moving all mounting elements of the crusher jaw from the wear area A more even material flow may be affected if the transfer from the prescreen or the feeder trough is designed so material simply tilts into the crushing jaw 2:Check vibrating screen mesh and jaw crusher wear parts at fixed interval,reduce the maintenace and jaw crusher blockage and prolong jaw crusher service life 3:When the jaw crusher blockage appears in the outlet,stop the vibrating screen working and turn off jaw crusher power source,then adjust the belt conveyor and restart the jaw parative advantages and disadvantages of cone More, Sunil JRajpal, " A Review on Study of Jaw Plates of Jaw Crusher ", International Journal of Modern Engineering Research (IJMER), Vol3, Issue1, JanFeb 2013 pp518522 Show more Optimization of Effect of Without Stiffener on Swing Figure 4 Jaw crusher stage with a screen in the grizzly bypass to extract a 090 mm product Figure 5 Jaw crusher stage with a screen that process all material and allows for production of 030 mm, 060 mm or 0‑90 mm Figure 6 The rock size varies in the muck pile, as seen in the picture the number of large rocks is far greater on the Designing a Crushing Screening Plant – Part I