gold ore chemical processing methods

2022-11-10T16:11:19+00:00

The Gold Ore Processing Methods According to The

01 The processing method of gold ore with easyseparation The gold ore with easyseparation is mostly oxide gold ore and sulfide gold ore The gold recovery rate can generally reach more than 90%, and cyanide leaching is often used to recover gold supplemented by CIP or CILFlotation is one of the most widely used methods for gold ore processing Through this method, gold can not only be enriched into sulfide mineral concentrate to the maximum extent, but also waste tailings, with low beneficiation cost Cyanidation; It refers to the process of Collection of Gold Ore Processing Methods, Gold According to the degree of ore oxidation, gold ore can be divided into primary (sulfide ore) ore, partially oxidized (mixed) ore and oxidized ore Here are the different kind of gold ore processing methods used for five types of gold ore Let's drive in nowDifferent Gold Ore Processing Methods for 5 Kinds of Gold Processing Methods Gold Ore Extraction Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that involved flotation, cyanidation and gravity concentrationGold Ore Processing Methods droemerarchitektende Easily extracted gold ore has long been a major source of gold production in countries around the world, and such resources will be declining due to longterm mining In the paper, I list 5 Easily Extracted Gold Ores and 8 Processing Methods, let’s read 5 Easily Extracted Gold Ores and 8 Processing

Processing, smelting and refining gold World Gold

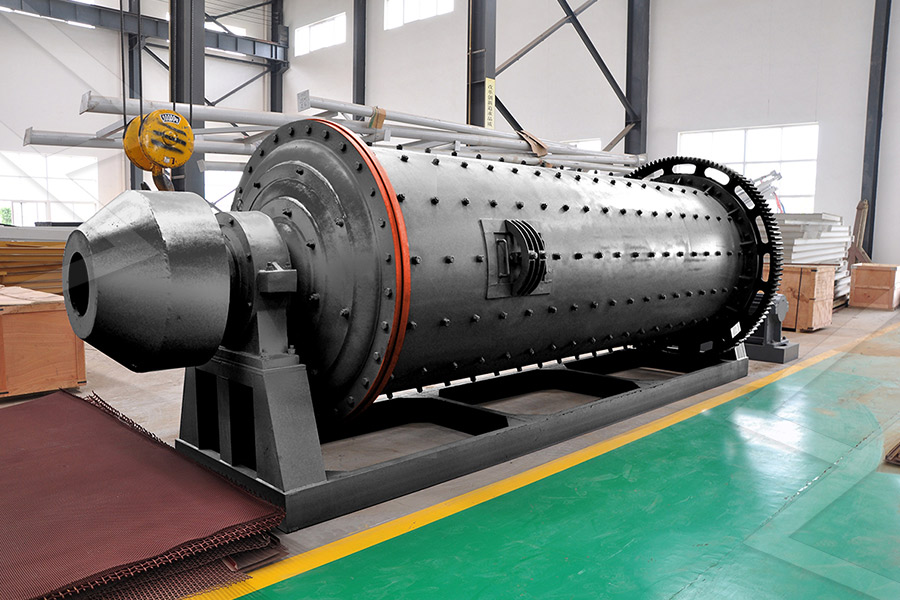

Processing, smelting and refining gold From ore to doré With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitators The two gold refining methods most commonly employed to Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing Gold processing Mining and concentrating Britannica In order to extract gold, it is necessary to crush and grind the ore to suitable size and then separate the gold from the ore using specific mineral processing method and gold recovery chemicals At present, gravity separation, flotation separation, heap leaching and cyanidation (CIL,CIP) are four commonly used gold recovery methodsWhat Are Commonly Used Gold Recovery Chemicals? Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design Methods for chemical characterization, visible gold characterization and "invisible" gold characterization are all investigated and the most comprehensive set of methods discussed Ores from the Pilbara region of Western Australia are examined as examples of complex gold ores with varying mineralogy and metallurgical behaviourNew techniques in the characterisation of complex

The Extraction of Gold by Chemical Methods Nature

EXCLUDING mechanical, smelting, and amalgamation processes, the methods of extracting gold from its ores may conveniently be grouped together under the heading of wet or chemical methods In these In order to extract gold, it is necessary to crush and grind the ore to suitable size and then separate the gold from the ore using specific mineral processing method and gold recovery chemicals At present, gravity separation, flotation separation, heap leaching and cyanidation (CIL,CIP) are four commonly used gold recovery methodsWhat Are Commonly Used Gold Recovery Chemicals? Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing EBook Gold Ore Processing Free in PDF, Tuebl, Docx the wellknown chemical inertness of the noble metal toward most acids and bases3 Several reagents are known to leach native gold from goldbearing ores It has been known for more than a century that alkaline solutions of alkalimetal cyanides (eg, NaCN, KCN) dissolve gold under aerated conditions The dissolution of metallic gold is due A Method for Leaching or Dissolving Gold from Ores or Going for gold: Alternative processing methods January 17, unlike coal processing, gold processing currently involves the use of environmentally hazardous cyanide, adding a raft of legal and Going for gold: Alternative processing methods

Gold extraction QueensMineDesignWiki

Gold ore can be classified as freemilling, complex, or refractory and each type of ore has different challenges when it comes to processing methods Cyanidation with CIL/ CIP continues to be the most common method, although there are environmental concerns due to toxicity A moderately low grade of the bulk ore and the additional processing costs involved in whole ore treatment processes are most certainly not economically viable and therefore not being considered A significant proportion of the sulphidic refractory gold appears to be hosted by the arsenical pyrite, arsenopyrite and stibnite components of the oreSulphidic refractory gold ore pretreatment by Gold deposits can be grouped into two primary classes: placer deposits, where the gold is exposed from weathering and erosion, and hard rock, where the gold is still trapped within the host rock Gold recovery methods for these two types of deposits vary greatly from simple panning to a complex network of grinding, chemical leaching, gravity Gold Recovery And How To Choose The Right Process The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing MethodsChemical operations, for the separation and refining of the individual metals Smelting Operations Converter matte from Rustenburg arrives at the Brimsdown smelter in bags of about 150 pounds each It has been crushed to threeinch size After weighing and sampling the first operation is to separate the nickel and copper sulphidesExtraction and Refining of the Platinum Metals

Gold Ore Processing Methods Cost In Uzbekistan

The Pure Gold Can Be Extracted From The Rock By Initially Crushing The Quartz And Conducting Further Processing On The Gold Ore Gold Is A Chemical Element With Symbol Au And Atomic Number 79 In Its Purest Form, It Is A Bright, Slightly Reddish Yellow, Dense, Soft, Malleable, And Ductile Metal Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms Gold processing Britannica Information Circular 8770 Processing Gold Ores Using Heap LeachCarbon Adsorption Methods By H J Heinen, D G Peterson, and R E Lindstrom UNITED STATES DEPARTMENT OF THE INTERIOR Cecil D Andrus, Secretary BUREAU OF MINESProcessing Gold Ores Using Heap LeachCarbon Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing EBook Gold Ore Processing Free in PDF, Tuebl, Docx The gold ore is then pulverized using pressure to create very fine particles These fine particles are then heated in a furnace to temperatures above 1064 degrees Celsius the melting point of gold The heating process burns most of the impurities but some like other metal elements remain 2 Presmelting Chemical Removal Some chemicals found The Gold Smelting Process Melting, Smelting

A Method for Leaching or Dissolving Gold from Ores or

the wellknown chemical inertness of the noble metal toward most acids and bases3 Several reagents are known to leach native gold from goldbearing ores It has been known for more than a century that alkaline solutions of alkalimetal cyanides (eg, NaCN, KCN) dissolve gold under aerated conditions The dissolution of metallic gold is due Leaching dissolves the gold out of the ore using a chemical solvent The most common solvent is cyanide, which must be combined with oxygen in a process known as carboninpulp As the cyanide and oxygen react chemically, gold in the pulp dissolves When workers introduce small carbon grains to the tank, the gold adheres to the carbonExtracting Gold HowStuffWorks Simplifying sample processing: New gold assay method offers faster turnaround A new gold assay method could offer a faster, simpler alternative to fire assaying It also provides valuable information on which mineral extraction and processing methods to employ to maximize the value of the finished product T he chemical analysis of Simplifying sample processing: New gold assay The two are actually different methods, but both involve heating the ore to high temperatures Technically, any methods which consist of processing ore by heating it are called “pyrometallurgy” The old timers took advantage of the chemical instability of sulfides by simply heating (or roasting) them to burn off the sulfurSmelting and Roasting Ores to recover gold, silver and